Components of the highest quality - customized, precise, future-oriented.

Too complex? No such thing. At AHWION, we have developed innovative technologies and manufacturing processes that allow us to machine components of all kinds—no matter how challenging. The result of our expertise is a broad product portfolio featuring parts and assemblies from various cutting-edge areas of the automotive industry.

New solutions for the industry: our business areas

Our aspiration is to develop visions for the automotive industry together with our customers. That’s why we focus on business areas that not only drive us today, but also shape the world of tomorrow—sustainably and innovatively.

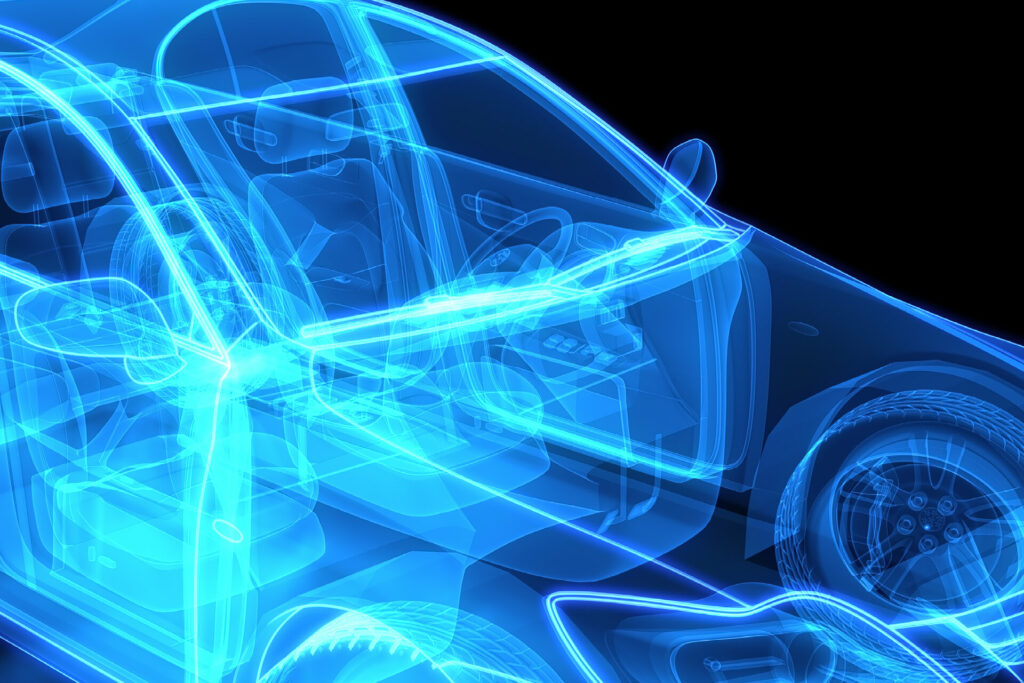

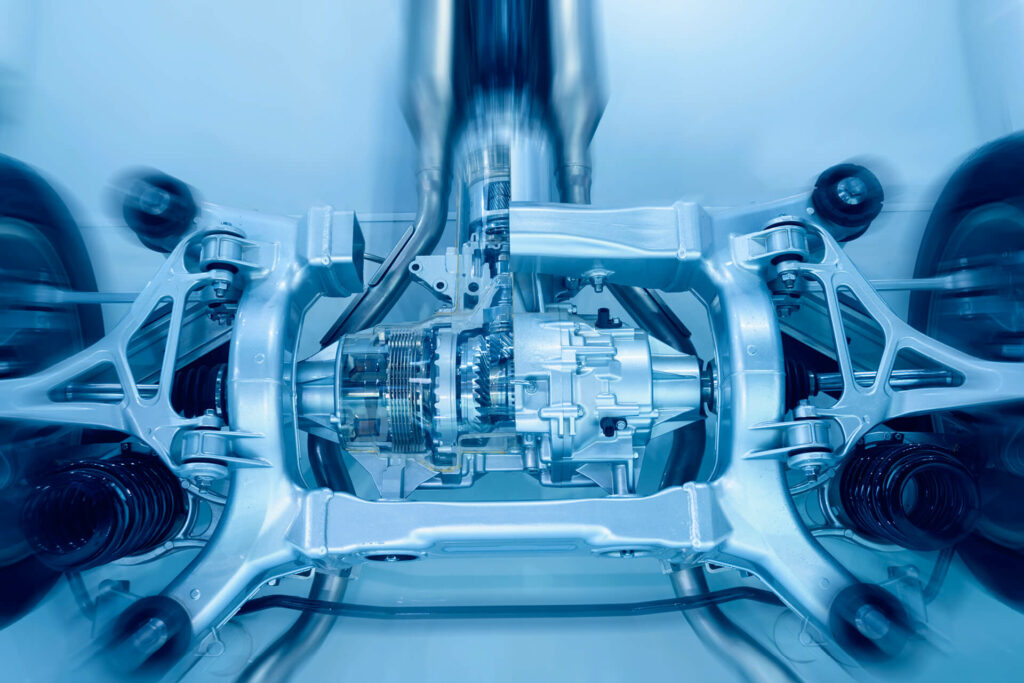

Chassis

E-mobility

Hydrogen technology

Our product portfolio:

Pioneering solutions for every application: together with our customers, we create components and assemblies that meet today’s challenges while laying the foundation for sustainable, future-oriented mobility. How do we do this? By placing no limits on even the most complex requirements

Production with all steel materials

No two steel materials are the same. With our core competencies, we have the expertise to process a wide variety of steel materials for you.

Diverse range of realizable specifications

With a maximum part diameter of 60 mm or 70 mm free-flowing, we bring the flexibility to customize your parts according to your individual requirements:

The result of our technological expertise:

Shaft in unprocessed state

Shaft in processed state

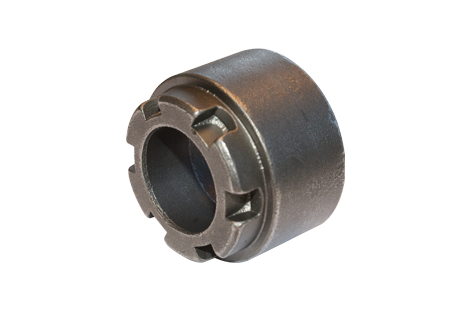

Crown nut in unprocessed state

Crown nut in processed state

Valve body (or valve housing)

in unprocessed state

Valve body (or valve housing)

in processed state

Your partner beyond the production process

We don’t just produce highly complex parts—we also provide strong development services, leveraging our tooling expertise.

Analysis of different properties:

Whether chemical, physical, (structural) mechanical or technical manufacturing properties – AHWION has various analysis options.

Numerical analysis:

We offer numerical analysis capabilities of both forming and structural mechanics, including fully coupled simulation in 2D and 3D.

Measuring laboratories

In our measurement laboratories, we perform optical, tactile and attributive measurements and tests in accordance with IATF standards.

Optimization of processes:

Our interdisciplinary development team optimizes your processes across the entire supply chain.

Testing:

We test the anti-corrosion effect of coated components for you in accordance with DIN EN ISO 9227, DIN 50018, DIN EN ISO 6270-2, ASTM B-117.

Setting component properties:

We set specific (local) component properties for you through a defined design, material and process combination.